R & D team

and core technology

Coyo's R&D team is a high-tech talent team with more than 10 years of work experience, focusing on the research and development of aluminum alloy profile products in the field of industrial equipment automation, optics, smart security, smart medical and smart home, etc. The core technology innovation mode of materials, technology, design and product development.

In the past years, exploration and accumulation are what we have always adhered to. The pursuit of product production details has earned the company's products the recognition of customers at home and abroad, and has outstanding trust among customers, becoming the industry's integrity brand.

At the same time, many years of hard work have yielded fruitful results. The company and its products have won a number of honors, not only affirming the company's products, but also motivating all employees to move forward to a more ambitious blueprint and climb new heights.

Quality Introduction

Survive by quality, develop by service.

Business operation is not only an economic benefit. It is also an inherent obligation of the enterprise to abide by corporate ethics and manufacture exquisite products. All Shuai Feng adhering to the dedication and excellence of the craftsman spirit, overcoming impetuousness,

digesting and absorbing advanced manufacturing concepts and methods from Japan and Germany, strictly controlling the five major elements of people, equipment, materials, processes and the environment that affect quality, a systematic and standardized process We listen to user suggestions and continuous improvement (PDCA) to ensure the value experience that product quality brings to users.

Production Process

1. Design

2. Plan to confirm

3. Furnace purification & forging

4. Homogeneous

5. Mold repair

6. Squeeze

7. Straightening

8. Cutting

9. Aging Furnace

10. (FQC)Measurement

11. CNC machining

12. Homogeneous

CNC Precision Machining

The machining accuracy of the punch box parts is the framework for the overall accuracy of the punch.

The box castings of Yingjun punching machine have been subjected to long-term stress aging, and then processed by top-level high-precision CNC machining centers, and imported CMM testing.Make the accuracy stable and consistent, and ensure long-term stability of product accuracy.

High Accuracy

CNC programming is the basis of CNC machining. The quality of the machining program of the workpiece will directly affect the machining efficiency of the workpiece. We use a combination of inherent programs and automated programming to reduce the error of the CNC system, flexibly use the main program, and improve programming. speed, simplifying the machining tool path.

High-precision rolling bearings are selected to improve the rotation efficiency of the bearing and improve the accuracy of the parts matched with the bearing.General CNC accuracy tolerance: +/-0.005mm ~ +/-0.1mm.Surface roughness: Ra 1.6~3.2.

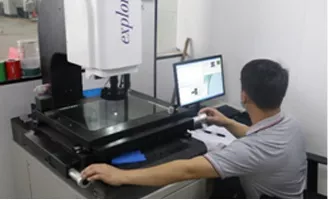

Product Testing

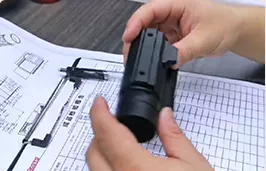

01Parts inspection

Strict quality inspection standards and systematic testing processes ensure that the size of each component is accurate and in line with the requirements of design drawings.

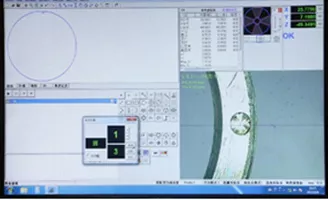

02Performance requirements testing

Each of Coyo's processed products must be tested for performance requirements to ensure the stability of motion structure changes during production, product stability and the working life of core components.

03Molecular structure detection

Molecular structure detection is to verify whether the product meets the design requirements of the internal molecular structure balance mathematical model in acid etching, alkali etching, low magnification microscope, metallographic microscope, scanning electron microscope and other equipment to ensure that all meet the customer's design requirements and satisfy customers Production.